BT Laminate Substrate Manufacturer

BT Laminate Substrate Manufacturer,BT laminate substrate is a high-performance material used in the manufacturing of printed circuit boards (PCBs), named after its primary component—Bismaleimide Triazine (BT) resin. This resin possesses excellent thermal stability and mechanical strength, making BT laminate substrate an ideal choice for high-frequency and high-speed electronic applications. Its low dielectric constant and low loss tangent make it perform exceptionally well in signal transmission, while maintaining excellent signal integrity and interference resistance. BT laminate substrate finds widespread applications in communication equipment, radar systems, aerospace applications, high-speed digital circuits, and more, meeting the demanding requirements of reliability and performance stability. When selecting and designing BT laminate substrate, designers need to consider factors such as the operating frequency of the circuit, thermal management requirements, electrical performance, and manufacturability to ensure the final product’s performance and reliability.

What is a BT Laminate Substrate?

A BT laminate substrate refers to a type of printed circuit board (PCB) material that is commonly used in electronic devices. “BT” stands for “bismaleimide triazine,” which is a type of resin used in the laminate. This resin provides excellent thermal and mechanical properties, making it suitable for high-frequency and high-speed applications.

BT laminate substrates are known for their stability over a wide range of temperatures, as well as their low dielectric constant and loss tangent, which are important for maintaining signal integrity in high-frequency circuits. These properties make BT laminate substrates popular choices for applications such as telecommunications, wireless communication, and high-speed digital electronics.

Overall, BT laminate substrates offer a good balance of electrical performance, thermal stability, and mechanical strength, making them a preferred choice for many PCB designs.

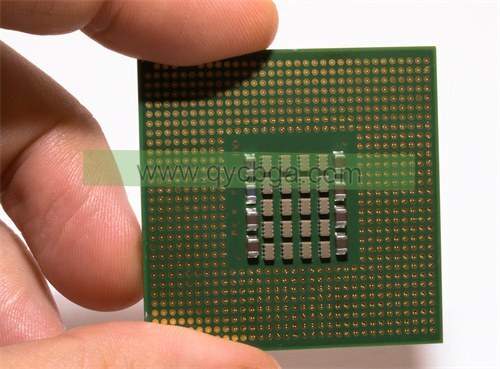

BT Laminate substrate Manufacturer

What are the BT Laminate Substrate Design Guidelines?

Design guidelines for BT laminate substrates typically include considerations related to material properties, signal integrity, thermal management, and manufacturability. Here are some common guidelines:

- Material Selection:Choose the appropriate grade of BT laminate substrate based on the specific requirements of your design, such as operating frequency, thermal performance, and mechanical strength.

- Dielectric Constant and Loss Tangent: Understand the dielectric constant and loss tangent of the BT laminate substrate, as these properties affect signal integrity, especially in high-frequency applications. Minimize signal loss and distortion by selecting materials with low dielectric constant and loss tangent.

- Trace Width and Spacing: Follow recommended trace width and spacing guidelines to ensure proper impedance matching and signal integrity. These guidelines are often provided by the manufacturer or can be calculated using impedance calculators.

- Via Design: Design vias carefully to minimize signal reflections and impedance mismatches. Consider using techniques such as via stitching and proper via placement to maintain signal integrity and reduce electromagnetic interference (EMI).

- Thermal Management: Pay attention to thermal management considerations, especially in designs with high-power components or in environments with elevated temperatures. Ensure adequate heat dissipation through the PCB layout, such as using thermal vias and thermal relief pads.

- Manufacturability: Design the PCB layout with manufacturability in mind, considering factors such as panelization, solder mask requirements, and assembly processes. Follow design for manufacturability (DFM) guidelines provided by the PCB manufacturer to minimize production issues.

- Stackup Design: Optimize the layer stackup configuration to meet the electrical and mechanical requirements of the design. Consider factors such as controlled impedance layers, power and ground plane distribution, and signal routing considerations.

- Environmental Considerations: Evaluate the environmental conditions in which the PCB will operate and ensure that the BT laminate substrate can withstand these conditions, such as temperature extremes, humidity, and chemical exposure.

- Compliance and Standards: Ensure that the PCB design complies with relevant industry standards and regulations, such as IPC standards for PCB design and fabrication, as well as specific requirements for the intended application.

- Simulation and Testing: Utilize simulation tools and conduct thorough testing to validate the design and ensure that it meets performance requirements before manufacturing. Perform signal integrity analysis, thermal simulations, and prototype testing as necessary.

By following these guidelines, designers can effectively leverage BT laminate substrates to achieve optimal performance, reliability, and manufacturability in their PCB designs.

What is the BT Laminate Substrate Fabrication Process?

The fabrication process for BT laminate substrates involves several steps, including material preparation, layer buildup, etching, drilling, plating, and finishing. Here’s an overview of the typical process:

- Material Preparation: The fabrication process begins with preparing the BT laminate material. This involves cutting the laminate sheets to the required size based on the design specifications.

- Layer Stackup: Multiple layers of BT laminate are stacked together according to the desired layer configuration. Each layer may contain copper foil bonded to the laminate substrate.

- Lamination: The layer stackup undergoes lamination under heat and pressure to bond the layers together into a single composite structure. This process ensures good adhesion between the laminate layers and the copper foils.

- Circuit Patterning: A layer of photoresist is applied onto the copper foil surfaces. Then, the desired circuit patterns are transferred onto the photoresist using photolithography techniques. This involves exposing the photoresist to UV light through a photomask and developing it to remove the unexposed areas, leaving behind the patterned resist.

- Etching: The exposed copper areas not protected by the developed photoresist are etched away using chemical etchants. This step removes the unwanted copper, leaving behind the circuit traces according to the patterned resist.

- Drilling: Holes are drilled into the substrate where vias and component mounting holes are required. High-speed drilling machines are used to accurately drill holes of various sizes through the laminate stack.

- Desmear and Etchback: After drilling, the drilled holes are cleaned and chemically treated to remove any smear or debris generated during the drilling process. Etchback is performed to remove excess resin from the walls of the drilled holes, exposing the copper for subsequent plating.

- Plating: Copper plating is applied to the walls of the drilled holes and the exposed copper surfaces to enhance conductivity and provide interconnection between layers. Electroless copper plating followed by electrolytic copper plating is commonly used in this process.

- Surface Finish: The exposed copper surfaces are coated with a surface finish to protect them from oxidation and facilitate soldering during assembly. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservatives).

- Final Inspection: The fabricated PCB undergoes visual inspection, dimensional measurement, electrical testing, and other quality checks to ensure that it meets the required specifications and standards.

- Routing and Profiling: The fabricated PCB is routed to separate individual boards from the panel, and the edges are profiled to the final dimensions.

- Final Testing and Quality Assurance: The finished PCBs undergo final testing to verify functionality and quality before being shipped to the customer.

This fabrication process yields high-quality BT laminate substrates ready for component assembly and integration into electronic devices.

How do you manufacture a BT Laminate Substrate?

Manufacturing a BT laminate substrate involves several steps, including material preparation, layer buildup, bonding, pressing, drilling, plating, and finishing. Here’s a detailed overview of the manufacturing process:

- Material Preparation:

– Raw materials, including BT resin and reinforcement materials such as glass or woven fiberglass, are prepared according to the desired specifications.

– BT resin is typically supplied in the form of sheets or rolls, while reinforcement materials are often in the form of woven fabric or pre-preg (pre-impregnated resin).

– The BT resin may be mixed with additives to enhance specific properties such as thermal conductivity or flame resistance.

- Layer Buildup:

– Multiple layers of BT laminate are stacked together with the reinforcement materials in between.

– Copper foil sheets may be bonded to the outer layers of the laminate stack to form the conductive layers for the PCB.

- Bonding:

– The layer stack is bonded together using heat and pressure. This process, known as lamination, ensures proper adhesion between the layers and removes any air or voids between them.

- Pressing:

– The bonded layer stack undergoes pressing in a hydraulic press or similar equipment to further consolidate the layers and achieve the desired thickness.

- Drilling:

– Holes are drilled into the laminate stack where vias and component mounting holes are required.

– High-precision CNC drilling machines are used to accurately drill holes of various sizes and configurations.

- Plating:

– Copper plating is applied to the walls of the drilled holes and the exposed copper surfaces to create conductive pathways between layers.

– Electroless copper plating followed by electrolytic copper plating is commonly used to achieve the desired copper thickness and conductivity.

- Surface Finishing:

– The exposed copper surfaces are coated with a surface finish to protect them from oxidation and facilitate soldering during assembly.

– Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservatives).

- Final Inspection:

– The manufactured BT laminate substrates undergo thorough inspection and testing to ensure that they meet the required specifications and standards.

– Visual inspection, dimensional measurement, electrical testing, and other quality checks are performed to verify the quality and integrity of the substrates.

- Packaging and Shipping:

– The finished BT laminate substrates are packaged according to customer requirements and shipped to their destination for further processing or assembly into electronic devices.

By following these manufacturing steps with precision and quality control measures, manufacturers can produce high-quality BT laminate substrates suitable for a wide range of electronic applications.

How much should a BT Laminate Substrate cost?

The cost of a BT laminate substrate can vary significantly depending on several factors, including the material specifications, size, thickness, copper weight, surface finish, and quantity ordered. Additionally, market demand, supplier pricing, and economic conditions can also impact the cost.

As a rough estimate, the cost of a standard BT laminate substrate without copper layers or surface finish can range from a few dollars per square foot to around $10 or more per square foot. However, this is just for the raw material itself and does not include additional costs such as fabrication, processing, or finishing.

Adding copper layers through processes such as electroplating will increase the cost, as will applying surface finishes like ENIG or OSP. The complexity of the design, including the number of layers, drill holes, and special requirements, will also affect the overall cost.

For a more accurate cost estimate, it’s best to contact PCB manufacturers or suppliers directly and provide them with detailed specifications for your specific project. They can then provide you with a quote based on your requirements and quantities needed.

What is BT Laminate Substrate Base Material?

The base material of a BT laminate substrate is typically composed of a resin known as bismaleimide triazine (BT resin). This resin serves as the matrix material in the laminate, providing mechanical support and insulation properties for the PCB.

BT resin is a thermosetting material known for its excellent thermal stability, mechanical strength, and electrical properties, making it well-suited for use in high-frequency and high-speed electronic applications. It has a relatively low dielectric constant and loss tangent, which are important for maintaining signal integrity in PCB designs.

In addition to BT resin, the base material of a BT laminate substrate may also include reinforcement materials such as woven fiberglass or glass fabric. These reinforcement materials help enhance the mechanical properties of the laminate, such as tensile strength and dimensional stability.

Overall, the combination of BT resin and reinforcement materials forms the base material of a BT laminate substrate, providing the foundation for the PCB structure and contributing to its overall performance and reliability.

Which company makes BT Laminate Substrates?

BT laminate substrate is a common material used in electronic devices, widely applied in high-frequency and high-speed circuits. Currently, there are several companies producing BT laminate substrates, including well-known PCB material manufacturers such as Rogers Corporation, Isola Group, Nelco Products, etc.

As a material processing company, our company is also capable of producing BT laminate substrates. We have advanced production equipment and a skilled technical team to provide high-quality, customized BT laminate substrate products. Our production process covers multiple stages from material preparation to lamination, molding, drilling, copper plating, surface treatment, etc., ensuring controlled and stable product quality. Additionally, we have rich production experience and professional knowledge to customize BT laminate substrates with different specifications, thicknesses, and layer counts according to customer requirements, meeting various application scenarios’ demands.

The BT laminate substrate products from our company have the following features and advantages:

- High-Quality Materials: We use high-quality BT resin and reinforcement materials to ensure the products have excellent electrical performance, thermal performance, and mechanical strength.

- Customized Services: We can customize BT laminate substrates with different specifications, thicknesses, and layer counts according to customer requirements, providing personalized solutions.

- Strict Quality Control: We strictly follow the ISO quality management system for production management to ensure stable and reliable product quality, meeting relevant standards and requirements.

- Fast Delivery: With efficient production capacity and supply chain management system, we can timely meet customer order requirements, ensuring prompt delivery.

Through the BT laminate substrates produced by our company, customers can obtain high-quality and reliable products to meet their application needs in various electronic devices. We will continue to improve product quality and technical capabilities to provide better services and support to customers.

What are the 7 qualities of good customer service?

Good customer service is characterized by several key qualities that contribute to positive interactions and satisfaction for customers. Here are seven qualities of good customer service:

- Responsiveness:Good customer service involves being prompt and responsive to customer inquiries, requests, and issues. Responding quickly to customer needs demonstrates attentiveness and a commitment to addressing concerns in a timely manner.

- Empathy: Empathy is the ability to understand and share the feelings of customers. Good customer service representatives demonstrate empathy by actively listening to customers, acknowledging their concerns, and showing genuine concern for their experiences.

- Clear Communication: Effective communication is essential for good customer service. Clear and concise communication helps customers understand information, instructions, and solutions. Good communication also involves being courteous, respectful, and using appropriate language and tone.

- Knowledgeability: Customers expect customer service representatives to have a good understanding of the products or services they offer. Being knowledgeable allows representatives to provide accurate information, answer questions confidently, and offer helpful solutions to customer problems.

- Problem-Solving Skills: Good customer service involves the ability to effectively resolve customer issues and problems. Customer service representatives should be skilled at identifying the root cause of problems, proposing viable solutions, and taking proactive steps to address customer concerns.

- Professionalism: Professionalism is essential for maintaining a positive customer service experience. This includes being courteous, respectful, and maintaining a professional demeanor in all interactions with customers. Professionalism also involves adhering to company policies and standards while assisting customers.

- Follow-Up: Good customer service doesn’t end with the resolution of a customer’s immediate issue. Following up with customers after their initial contact demonstrates a commitment to their satisfaction and helps ensure that their needs have been fully addressed. Following up also provides an opportunity to gather feedback and further enhance the customer experience.

By embodying these qualities, businesses can create positive interactions with customers, build trust and loyalty, and ultimately contribute to their long-term success.

FAQs (Frequently Asked Questions)

What is BT laminate substrate?

BT laminate substrate is a type of printed circuit board (PCB) material that uses bismaleimide triazine (BT) resin as its base. It is commonly used in high-frequency and high-speed electronic applications due to its excellent thermal and mechanical properties.

What are the advantages of using BT laminate substrate?

BT laminate substrate offers several advantages, including high thermal stability, low dielectric constant and loss tangent, good mechanical strength, and excellent signal integrity. These properties make it suitable for applications requiring reliable performance at high frequencies.

What are the typical applications of BT laminate substrate?

BT laminate substrate is used in various electronic devices and systems, including telecommunications equipment, wireless communication devices, radar systems, aerospace applications, high-speed digital circuits, and RF/microwave circuits.

How does BT laminate substrate compare to other types of PCB materials?

Compared to other PCB materials, BT laminate substrate offers superior thermal stability and signal integrity, particularly at high frequencies. It also has lower dielectric loss and better mechanical properties compared to materials like FR-4.

What are the key factors to consider when selecting BT laminate substrate for a project?

When selecting BT laminate substrate, important factors to consider include the operating frequency of the circuit, thermal management requirements, mechanical strength, desired electrical properties, and compatibility with manufacturing processes.

Is BT laminate substrate suitable for high-power applications?

While BT laminate substrate offers excellent thermal stability, it may not be the best choice for high-power applications that require exceptional heat dissipation. In such cases, alternative materials with higher thermal conductivity may be more appropriate.

Are there any special considerations for designing with BT laminate substrate?

Designing with BT laminate substrate requires attention to factors such as trace width and spacing for impedance control, via placement and design for signal routing, thermal management techniques, and compliance with industry standards for PCB design and fabrication.

Where can I purchase BT laminate substrate?

BT laminate substrate is available from various PCB material suppliers and distributors. It’s essential to choose a reputable supplier that offers high-quality materials and can provide technical support for your specific application needs.