ABF Package Substrate Manufacturer

ABF Package Substrate Manufacturer,ABF Package Substrates are advanced structural foundations utilized in semiconductor packaging. These substrates consist of multiple layers of dielectric and conductive materials meticulously engineered to provide exceptional thermal and electrical properties. With their high reliability and robust mechanical strength, ABF substrates enable efficient heat dissipation and reliable signal transmission within semiconductor packages. Their compatibility with high-density packaging solutions makes them ideal for various applications, including flip-chip packaging, ball grid array (BGA) packaging, system-in-package (SiP) modules, and multi-chip modules (MCMs). Designed to meet stringent performance requirements, ABF package substrates play a vital role in the development of high-performance electronic devices such as smartphones, tablets, and automotive electronics. Manufacturers adhere to strict quality control measures throughout the fabrication process to ensure consistent product quality and reliability. In essence, ABF Package Substrates represent a crucial component in the semiconductor industry, facilitating the seamless integration of integrated circuit components and ensuring the optimal performance of electronic devices.

What is an ABF Package Substrate?

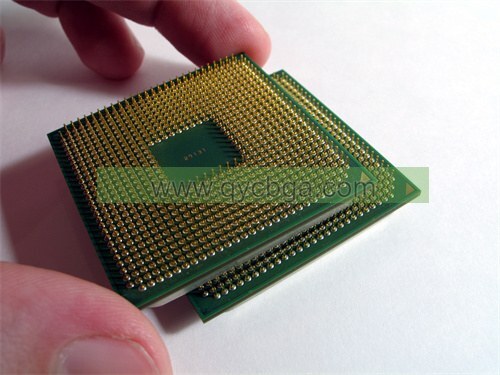

An ABF (Ajinomoto Build-up Film) package substrate is a crucial component in the manufacturing of semiconductor devices, particularly in advanced packaging technologies like flip-chip packaging. It serves as a structural foundation for mounting and interconnecting various integrated circuit (IC) components within a semiconductor package.

ABF substrates are made from epoxy-based materials and are characterized by their excellent thermal and electrical properties. These substrates provide a reliable platform for mounting IC chips, enabling efficient heat dissipation and electrical connectivity. The ABF material is engineered to have specific dielectric properties to minimize signal interference and ensure signal integrity within the package.

The manufacturing process of ABF substrates involves several steps, including film lamination, patterning, metallization, and etching. These processes result in the formation of intricate wiring patterns and interconnections that facilitate the transmission of signals between different components of the semiconductor package.

One of the key advantages of ABF package substrates is their compatibility with high-density packaging solutions. They allow for the integration of multiple IC chips within a compact footprint, which is essential for meeting the performance demands of modern electronic devices such as smartphones, tablets, and other portable gadgets.

Furthermore, ABF substrates offer excellent mechanical strength and reliability, ensuring the long-term performance and durability of semiconductor devices. They can withstand thermal cycling, mechanical stress, and other environmental factors without compromising their functionality.

In summary, ABF package substrates play a critical role in the development of advanced semiconductor packages, providing a robust foundation for mounting and interconnecting IC components. Their excellent thermal, electrical, and mechanical properties make them indispensable in the production of high-performance electronic devices.

ABF Package Substrate Manufacturer

What are ABF Package Substrate Design Guidelines?

Designing with ABF (Ajinomoto Build-up Film) package substrates involves adhering to specific guidelines to ensure optimal performance and reliability. Here are some common ABF package substrate design guidelines:

- Layer Stackup Design: ABF substrates typically consist of multiple layers of dielectric and conductive materials. The layer stackup design should be carefully planned to accommodate signal routing, power distribution, and thermal management requirements. The number of signal and power planes, their thickness, and their arrangement within the stackup are crucial considerations.

- Signal Integrity Considerations: Maintaining signal integrity is essential for reliable operation of semiconductor devices. Design guidelines should address signal routing, impedance matching, and signal termination techniques to minimize signal degradation, reflections, and crosstalk. Controlled impedance routing is often necessary to ensure consistent signal quality.

- Power Delivery Network (PDN) Design: Efficient power distribution is critical for supplying stable power to the IC components within the package. PDN design guidelines should include considerations for power plane placement, via stitching, decoupling capacitor placement, and minimizing impedance in the power distribution network.

- Thermal Management: Effective heat dissipation is essential for preventing overheating and ensuring the reliability of semiconductor devices. Design guidelines should incorporate thermal vias, thermal pads, and heat spreaders to facilitate heat transfer away from the IC components. Careful placement of high-power components and consideration of airflow within the package are also important.

- Routing and Via Design: Guidelines for routing signal traces and vias should optimize signal integrity, minimize signal skew, and ensure manufacturability. Differential pair routing, via placement, via size, and via types (e.g., through-hole vias, blind vias, buried vias) should be carefully considered to meet performance requirements while adhering to manufacturing constraints.

- Design for Manufacturability (DFM): Design guidelines should take into account manufacturing constraints such as minimum trace width and spacing, minimum via size, and alignment tolerances. Designing with manufacturability in mind helps avoid fabrication issues and ensures consistent production quality.

- Reliability Considerations: Design guidelines should address reliability concerns such as mechanical stress, thermal cycling, and solder joint integrity. Proper component placement, pad design, and reinforcement structures can enhance the reliability of the package substrate.

- Compliance with Standards: Design guidelines should ensure compliance with industry standards and specifications relevant to semiconductor packaging, such as JEDEC standards and IPC guidelines.

By following these ABF package substrate design guidelines, designers can create robust and reliable semiconductor packages that meet performance requirements while facilitating efficient manufacturing processes.

What is the ABF Package Substrate Fabrication Process?

The fabrication process of ABF (Ajinomoto Build-up Film) package substrates involves several sequential steps to create the multilayered structure needed for mounting and interconnecting semiconductor components. Here’s an overview of the typical ABF package substrate fabrication process:

- Substrate Preparation: The process begins with the preparation of a base substrate, often made of materials like laminate or silicon. The substrate is cleaned and inspected to ensure it meets the required specifications for flatness, cleanliness, and surface quality.

- Layer Build-Up: ABF substrates are built up using multiple layers of dielectric and conductive materials. The build-up process involves depositing thin layers of dielectric material (often epoxy-based) onto the substrate using techniques such as spin coating or lamination. Each layer is cured to form a solid film before the next layer is added.

- Patterning: After the dielectric layers are deposited, patterning is performed to define the conductive traces and vias that will form the interconnections within the substrate. Patterning can be achieved through processes like photolithography, where a photoresist is applied to the surface, exposed to UV light through a mask, and developed to create the desired pattern.

- Metallization: Once the patterns are defined, metallization processes are used to deposit conductive materials (typically copper) onto the substrate surface. Metallization can be achieved through techniques such as sputtering, electroplating, or chemical vapor deposition (CVD). The deposited metal forms the conductive traces and vias that will carry electrical signals within the substrate.

- Etching: After metallization, the excess metal is removed from the substrate surface through etching processes. Chemical etchants are applied selectively to dissolve the metal in areas not protected by the patterned photoresist, leaving behind the desired conductive traces and vias.

- Surface Finish: Once the conductive traces and vias are defined, a surface finish may be applied to the substrate to protect the exposed metal surfaces and enhance solderability. Common surface finishes include electroless nickel immersion gold (ENIG), organic solderability preservatives (OSP), and immersion tin or silver.

- Quality Control and Testing: Throughout the fabrication process, quality control measures are implemented to ensure the substrate meets the required specifications for dimensional accuracy, electrical performance, and reliability. Various tests, such as electrical continuity testing, impedance measurement, and thermal cycling tests, may be performed to validate the substrate’s functionality and durability.

- Final Inspection and Packaging: Once fabrication is complete, the substrates undergo final inspection to identify any defects or deviations from specifications. Approved substrates are then packaged and prepared for shipment to semiconductor assembly facilities, where they will be used for mounting and interconnecting IC components in semiconductor packages.

By following these fabrication steps and adhering to strict quality control measures, manufacturers can produce ABF package substrates that meet the demanding requirements of modern semiconductor packaging applications.

How do you manufacture an ABF Package Substrate?

Manufacturing an ABF (Ajinomoto Build-up Film) package substrate involves a series of intricate processes to create a reliable platform for mounting and interconnecting semiconductor components. Here’s a detailed overview of the manufacturing process:

- Substrate Preparation: The process begins with the preparation of a base substrate, typically made of materials like laminate, silicon, or glass. The substrate is cleaned thoroughly to remove any contaminants and inspected for defects. It’s essential to ensure the substrate’s surface is flat and uniform, providing a stable foundation for subsequent fabrication steps.

- Build-Up Film Deposition: ABF substrates are built up using multiple layers of dielectric material, often epoxy-based films. The dielectric films are deposited onto the substrate surface using techniques such as spin coating or lamination. Each layer is applied sequentially and cured to form a solid film before the next layer is added. The number of layers depends on the desired thickness and complexity of the substrate.

- Patterning: Once the dielectric layers are deposited, patterning is performed to define the conductive traces and vias that will form the interconnections within the substrate. Patterning is typically achieved through photolithography, where a photoresist material is applied to the surface, exposed to UV light through a mask, and developed to create the desired pattern. The pattern defines the locations where conductive materials will be deposited.

- Metallization: After patterning, conductive materials, typically copper, are deposited onto the substrate surface to create the conductive traces and vias. Metallization can be accomplished using techniques such as sputtering, electroplating, or chemical vapor deposition (CVD). The deposited metal adheres to the exposed areas of the substrate defined by the patterned photoresist, forming the desired conductive features.

- Etching: Excess metal is removed from the substrate surface through etching processes. Chemical etchants are applied selectively to dissolve the metal in areas not protected by the patterned photoresist, leaving behind the desired conductive traces and vias. The etching process ensures that the conductive features have precise dimensions and alignments.

- Surface Finish: Once the conductive traces and vias are defined, a surface finish may be applied to protect the exposed metal surfaces and enhance solderability. Common surface finishes include electroless nickel immersion gold (ENIG), organic solderability preservatives (OSP), and immersion tin or silver. The surface finish ensures reliable electrical connections during subsequent assembly processes.

- Quality Control and Testing:Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the substrate meets the required specifications for dimensional accuracy, electrical performance, and reliability. Various tests, such as electrical continuity testing, impedance measurement, and thermal cycling tests, may be performed to validate the substrate’s functionality and durability.

- Final Inspection and Packaging: Once fabrication is complete, the substrates undergo final inspection to identify any defects or deviations from specifications. Approved substrates are then packaged and prepared for shipment to semiconductor assembly facilities, where they will be used for mounting and interconnecting IC components in semiconductor packages.

By meticulously executing these manufacturing steps and adhering to stringent quality control standards, manufacturers can produce high-quality ABF package substrates that meet the demanding requirements of modern semiconductor packaging applications.

How much should an ABF Package Substrate cost?

The cost of an ABF (Ajinomoto Build-up Film) package substrate can vary significantly depending on various factors such as substrate size, complexity, layer count, material quality, manufacturing volume, and supplier pricing policies. Generally, ABF package substrates are considered a significant portion of the overall cost of semiconductor packaging.

Several cost components contribute to the total cost of ABF package substrates:

- Material Costs: The cost of raw materials, including dielectric films, conductive materials (e.g., copper), surface finish materials, and other consumables used in the fabrication process, can significantly impact the substrate cost.

- Manufacturing Process Costs:The fabrication process involves several steps, including film deposition, patterning, metallization, etching, surface finishing, and quality control. Each step incurs labor, equipment, energy, and overhead costs, which contribute to the overall manufacturing cost.

- Design Complexity: The complexity of the substrate design, including the number of layers, the density of features (e.g., traces, vias), and the level of precision required, can influence manufacturing complexity and, consequently, the cost.

- Volume Discounts: Larger production volumes often result in lower per-unit costs due to economies of scale. Manufacturers may offer volume discounts for higher quantities of substrates ordered.

- Supplier Relationships: The relationship between the substrate manufacturer and the semiconductor device manufacturer can impact pricing. Long-term partnerships or contracts may lead to preferential pricing arrangements.

- Quality and Reliability Requirements: Meeting specific quality standards and reliability requirements may entail additional manufacturing processes, testing, and quality control measures, which can affect the substrate cost.

- Market Conditions: Market dynamics, including supply and demand fluctuations, material availability, and competitive pressures, can influence substrate pricing.

Due to the complexity and variability of these factors, it’s challenging to provide a precise cost estimate for ABF package substrates without specific details about the substrate’s specifications and manufacturing context. Generally, semiconductor manufacturers assess their requirements and negotiate pricing with substrate suppliers based on their unique needs and budget considerations.

What is ABF Package Substrate base material?

The base material used for ABF (Ajinomoto Build-up Film) package substrates typically consists of multiple layers of dielectric material. These dielectric materials serve as the foundation upon which the conductive traces and vias are built to facilitate electrical connections within the substrate.

The dielectric materials used in ABF substrates are often epoxy-based films, which offer excellent thermal and electrical properties suitable for semiconductor packaging applications. Epoxy resins are known for their high dielectric strength, good thermal stability, and compatibility with various manufacturing processes.

ABF substrates are constructed by depositing thin layers of dielectric material onto a substrate surface and then patterning and metallizing these layers to create the desired circuitry. The dielectric layers provide insulation between conductive traces and help to minimize signal interference and crosstalk within the substrate.

In addition to epoxy-based films, other dielectric materials such as polyimide (PI) and liquid crystal polymer (LCP) may also be used in certain ABF substrate designs, depending on specific performance requirements and application needs. These alternative materials offer different properties and characteristics that may be advantageous in particular situations, such as higher temperature resistance or improved flexibility.

Overall, the choice of base material for ABF package substrates depends on factors such as electrical performance, thermal management, mechanical properties, and manufacturability, with epoxy-based films being the most commonly used material due to their well-established properties and suitability for semiconductor packaging applications.

Which company manufactures ABF Package Substrates?

Manufacturers of ABF Package Substrates include Panasonic, Shin-Etsu Chemical, Lingsen Precision, Amkor Technology, and Ibiden, among others. These companies have extensive experience and technical expertise in the semiconductor packaging industry, capable of providing high-quality ABF Package Substrates products.

At our company, we can also manufacture ABF Package Substrates. As a specialized provider of semiconductor packaging solutions, we have advanced production equipment and a skilled technical team dedicated to offering customized ABF Package Substrates solutions for our customers. Our manufacturing processes adhere to international standards, ensuring our products meet customers’ requirements for quality, performance, and reliability.

Key features and advantages of our ABF Package Substrates include:

- High-Quality Materials: We use premium materials such as high-performance epoxy resins to ensure our products have excellent electrical and thermal properties.

- Advanced Manufacturing Processes: With advanced manufacturing equipment and precision processing techniques, we can achieve complex circuit structures and high-density wiring designs.

- Customized Design: We can provide customized design solutions tailored to customers’ requirements, including stack-up structures, wiring plans, surface treatments, etc., to meet various application needs.

- Strict Quality Control: We implement rigorous quality control measures at every stage, from raw material procurement to production, to ensure stable and reliable product quality.

- Timely Technical Support: With a professional technical team, we can provide timely technical support and after-sales service to help customers solve any issues encountered during use.

In summary, as a specialized provider of semiconductor packaging solutions, our company has the capability and experience to manufacture ABF Package Substrates, offering customers high-quality, customized products, and services.

What are the qualities of good customer service?

Good customer service encompasses several qualities that contribute to a positive and satisfying experience for customers. Here are some key qualities of good customer service:

- Excellent Communication: Effective communication is essential for understanding customer needs, providing assistance, and resolving issues promptly. Customer service representatives should be attentive, clear, and courteous in their interactions with customers, whether it’s in-person, over the phone, or through digital channels.

- Empathy and Understanding: Empathizing with customers’ concerns and demonstrating understanding of their perspectives fosters trust and rapport. Customer service representatives should listen actively, acknowledge customers’ feelings, and show genuine empathy when addressing their inquiries or complaints.

- Product Knowledge: Having in-depth knowledge about products or services allows customer service representatives to provide accurate information, offer helpful recommendations, and address customers’ queries effectively. Continuous training and education ensure that representatives stay updated on product features, benefits, and troubleshooting techniques.

- Problem-Solving Skills: Good customer service involves resolving issues and concerns in a timely and efficient manner. Customer service representatives should be resourceful, proactive, and solution-oriented, taking ownership of problems and working diligently to find satisfactory resolutions for customers.

- Professionalism and Courtesy: Maintaining a professional demeanor and treating customers with respect and courtesy are fundamental aspects of good customer service. Even in challenging situations, customer service representatives should remain calm, patient, and polite, demonstrating professionalism at all times.

- Prompt Responsiveness: Timely responsiveness demonstrates commitment to customer satisfaction and helps build trust and loyalty. Whether it’s answering inquiries, addressing complaints, or following up on requests, providing prompt responses shows customers that their needs are valued and prioritized.

- Personalization: Tailoring interactions to meet individual customer needs and preferences enhances the overall customer experience. Customer service representatives can personalize interactions by using customers’ names, acknowledging past interactions, and offering personalized recommendations or solutions whenever possible.

- Transparency and Honesty: Being transparent and honest builds credibility and fosters trust between businesses and customers. Customer service representatives should provide accurate information, set realistic expectations, and communicate openly about any limitations or constraints.

- Consistency: Consistency in service delivery across all touchpoints helps maintain brand reputation and ensures a seamless customer experience. Establishing and adhering to standard procedures, service protocols, and quality standards contribute to consistency in customer service delivery.

- Follow-Up and Feedback: Following up with customers after resolving issues or completing transactions demonstrates commitment to their satisfaction and provides opportunities for feedback. Customer service representatives can seek feedback, address any remaining concerns, and express appreciation for customers’ business, fostering long-term relationships and loyalty.

By embodying these qualities, businesses can deliver exceptional customer service that exceeds expectations, builds customer loyalty, and contributes to overall business success.

FAQs

What is an ABF package substrate?

An ABF package substrate is a structural foundation used in semiconductor packaging. It consists of multiple layers of dielectric and conductive materials that facilitate the mounting and interconnection of integrated circuit (IC) components within a semiconductor package.

What are the advantages of ABF package substrates?

ABF package substrates offer several advantages, including excellent thermal and electrical properties, compatibility with high-density packaging solutions, robust mechanical strength, and reliability in harsh operating environments. They enable efficient heat dissipation, signal transmission, and power distribution within semiconductor packages.

How are ABF package substrates manufactured?

The manufacturing process of ABF package substrates involves several steps, including substrate preparation, layer build-up (deposition of dielectric films), patterning, metallization (depositing conductive materials), etching, surface finishing, quality control, and final inspection. These processes create the multilayered structure necessary for semiconductor packaging.

What are the applications of ABF package substrates?

ABF package substrates are commonly used in various semiconductor packaging applications, including flip-chip packaging, ball grid array (BGA) packaging, system-in-package (SiP) modules, multi-chip modules (MCMs), and other high-performance electronic devices such as smartphones, tablets, and automotive electronics.

What factors should be considered when designing with ABF package substrates?

When designing with ABF package substrates, factors such as layer stackup design, signal integrity considerations, power delivery network (PDN) design, thermal management, routing and via design, design for manufacturability (DFM), reliability considerations, and compliance with standards should be taken into account to ensure optimal performance and reliability.

Where can ABF package substrates be sourced?

ABF package substrates can be sourced from various semiconductor packaging material suppliers, including manufacturers like Panasonic, Shin-Etsu Chemical, Amkor Technology, and others. Semiconductor device manufacturers often work with these suppliers to procure ABF package substrates for their specific applications.

What are the cost considerations for ABF package substrates?

The cost of ABF package substrates can vary depending on factors such as substrate size, complexity, material quality, manufacturing volume, and supplier pricing policies. Generally, ABF package substrates are a significant portion of the overall cost of semiconductor packaging, and costs can be influenced by material costs, manufacturing process costs, design complexity, volume discounts, supplier relationships, quality and reliability requirements, and market conditions.